Design. Build. Inspire

"Shaping the Future Today"

STRUCTURAL STEEL DETAILING SERVICES | STEEL DETAILING SERVICES

STRUCTURAL STEEL DETAILING SERVICES | STEEL DETAILING SERVICES

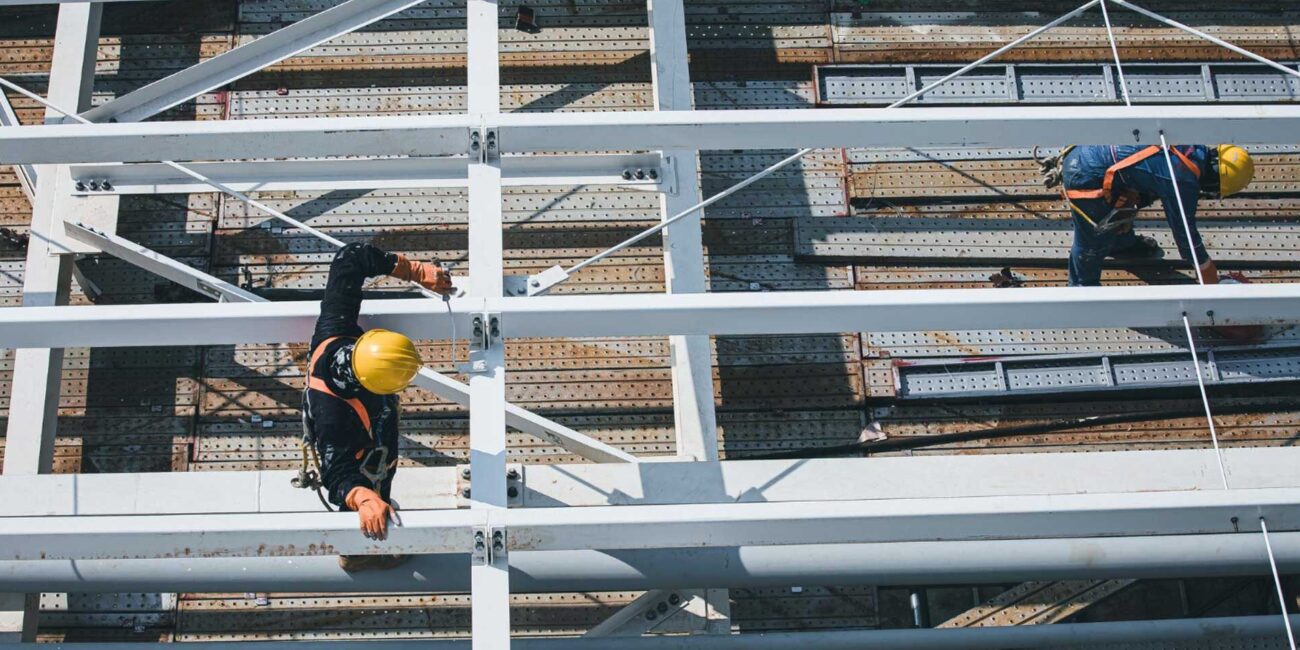

Structural steel detailing and design services are provided to clients worldwide by StelCode LLC. One of the top companies offering steel detailing services, we also offer approval drawings, CAD draughts, steel structure fabrication drawings, steel fabrication drawings, 2D drawings, and 3D models. Structural steel detailing is a significant and critical procedure in structural engineering services that requires around 99% accuracy and precision in the task. The structural engineering staff here ensures that there are no errors made that could waste precious time and money. Structural steel detailing services and steel fabrication detailing are crucial for all manufacturing and building activities. This set of work is related to the erection of commercial and residential projects, industrial plots, factories, institutes, hospitals, hotels, and much more.

A further name for this service is “communication link” because the entire process of steel detailing is a crucial means of communication. It does so by connecting important individuals and experts, such as architects, contractors, engineers, fabricators, and others who are involved in the project, based on this collection of information. Moving forward, we make sure that steel detailing is involved in the production of the detailed drawings needed by stakeholders like fabricators and contractors. Additionally, this full detailed service includes a variety of activities relating to reports and other significant and crucial labour. Shop drawings and erection drawings are the two main types of drawings used in this process.

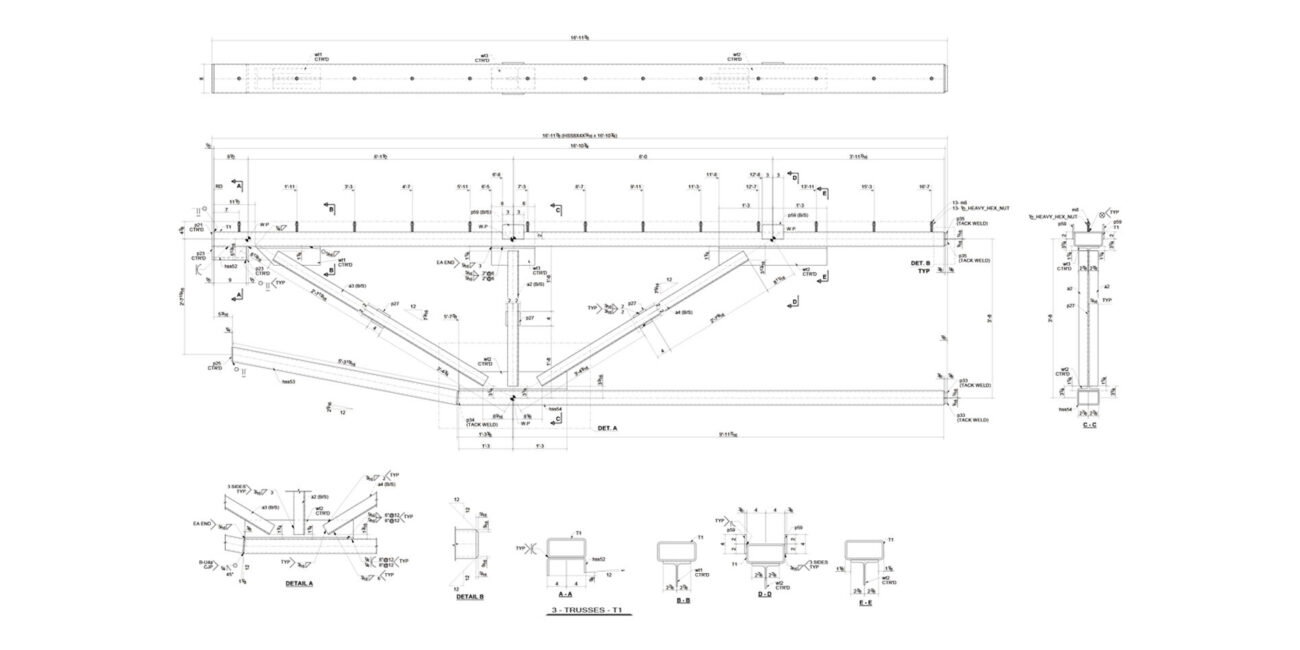

Shop Drawings

The set of drawings known as structural shop drawings to detail drawings include information about the specifics of particular steel parts and components. These components, which include columns, beams, joists, bracing, and trusses, are defined and created by steel fabricators. The information in this set of shop drawings helps contractors and construction workers move forward quickly and precisely. These drawings provide specifics about the materials, dimensions, sizes, components, surface specifications, painting details, and a great deal more information about each component's steel fabrication. These are the only relevant drawings for a fabrication team and fabrication units. The information provided here does not entirely include any details pertaining to the construction and installation of steel components.

Other significant steps in the steel detailing process include shop fabrication drawings, bill of materials (BoMs), precast panel detailing, rebar detailing, steel reinforcing details, steel design, Tekla steel detailing, and steel construction detailing.

Erection Drawings

Erection drawings are taken into account to obtain the specifications of each steel component in the overall structure. The main justification for it is because it gives precise information that is essential and depicts exact size plans. Here, our team of structural engineers discuss precise information that is relevant to the placement of each component, the information needed for installation, and field work-related information, such as the installation of bolts, wedges, welding sites, anchors, and other specifics.

Reports

STEEL DETAILING STANDARDS

The procedure of complying to various steel detailing standards, which are necessary and required for different countries, must be followed by the steel detailers. Some of the steel detailing requirements that we adhere to are listed below.

Structral Steel Detailing Services

The internal team of structural engineers has a broad range of knowledge and expertise to develop steel drawings, designs, and reports that are in compliance with the required hardware, software, and standards. A list of some of the services we provide is provided below.

Popular/General Structral Detailing

Drawings and paperwork are essential. This set of paperwork comprises the specific information needed for precise drawings, such as a drawing register, cutting list, summaries, locations, erection drawings, etc.

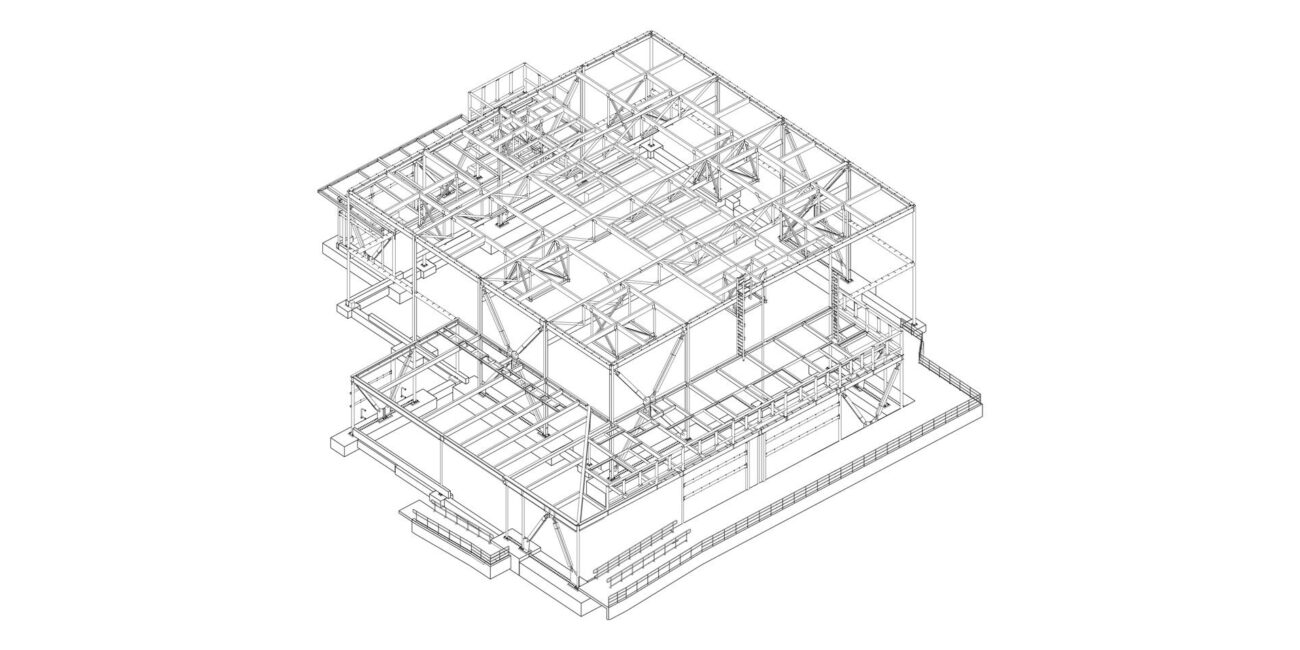

3D Modeling & 3D BIM Erection Drawings

Modern 3D modelling and BIM software is used by engineers to produce extremely accurate and comprehensive 3D steel models and 3D BIMerection drawings. The data needed for the site's construction are present in this information.

Framing Plans

Our team of engineers uses accurate drawings and blueprints that are considered to be a part of producing steel framework during the framing process. The ability to create these frames or frameworks from scratch to meet specific needs and requirements helps to expedite the work process and its many phases of completion.

Steel Connection Design

Steel connections, fittings, and fixtures are shown in great detail in the engineering team's designs. The information about how connections are made and how specifics are incorporated into designs and drawings is shared at this stage of the project.

Shop Fabrication Drawings

Bill Of Materials (BoMs)

The full costs and quantities of the items, as well as the list of needs, must be contained in a detailed and comprehensive bill of materials. This is a crucial component of the service and is one of its most critical elements.

Anchor Bolts Plans

Embedded Material Plans

Steel Estimation Reports

WHY SELECT STELCODE LLC FOR STRUCTURAL STEEL DETAILING SERVICES OUTSOURCING

Steel detailing services are a crucial component and service in the building industry. This is due to the fact that every steelwork is thoroughly inspected and monitored, providing the highest level of precision for the work. We have a unique group of structural engineers who can provide a wide range of services, including fabrication drawings, structural design, and drafting. The list of reasons why you should choose us as your outsourcing partner is provided below.

Team of Experienced Structural Engineers

We have a group of the greatest structural, civil, or mechanical engineers who have worked on projects involving steel details of all sizes and complexity for many years. Having said that, it means that in order to provide flawless structural steel detailing services, we adhere to the necessary norms and industry codes.

Supply of Simple to Complicated Designs

No matter what the client's requirements are, our engineers are skilled at completing the assignment. Whether our clients require straightforward geodesic design or intricate frame detailing. We have experience working on a range of projects, making us versatile in our understanding of the demands and requirements that our clients place on us.

Adhesion of Equipment and Software

We employ the most recent technologies and software necessary for the project's effective completion. With years of expertise, we have a solid understanding of how to use programmes like Advance Steel, Tekla, ProSteel, and STAADPro. as well as Trimble and Tekla.

Correct Incorporation of CAM Techniques

Drawings for fabrication can be created and developed to work with CAM (computer-assisted manufacturing) instruments, such as CNC machining. To produce and prepare designs and models that are ready for quick and immediate manufacture, CNC code is employed and applied.

Collaboration —

Let's work together.

The plans you refer to will soon be back in our hands. Alderaan? I'm not going to Alderaan. I've got to go home.

Stelcode llc

StelCode Detailing LLC is a trusted engineering firm specializing in Structural Steel Detailing and engineering solutions for a wide range of projects, including Industrial, Commercial, Residential, and Institutional structures.

American Institute of Steel Construction

OUR PROJECTS

Industrial

Residential

School

Pipe Rack Steels

Stair Towers

Garage/Warehouse

Hospital

Commercial Building

CONTACT US

StelCode Detailing LLC

614 N Dupont HWY, Suite 210, Dover, 19901 Delaware

Call Us

704-842-3159

StelCode Engineering Services Pvt. Ltd.

#25, 2nd Floor, BNN Mansion 1st Main Road, 80ft Road, 43rd Cross, Jayanagar 8th block, Bangalore 82

Call Us

+91 97422 67066

Mail Us

info@stelcode.com